Technology

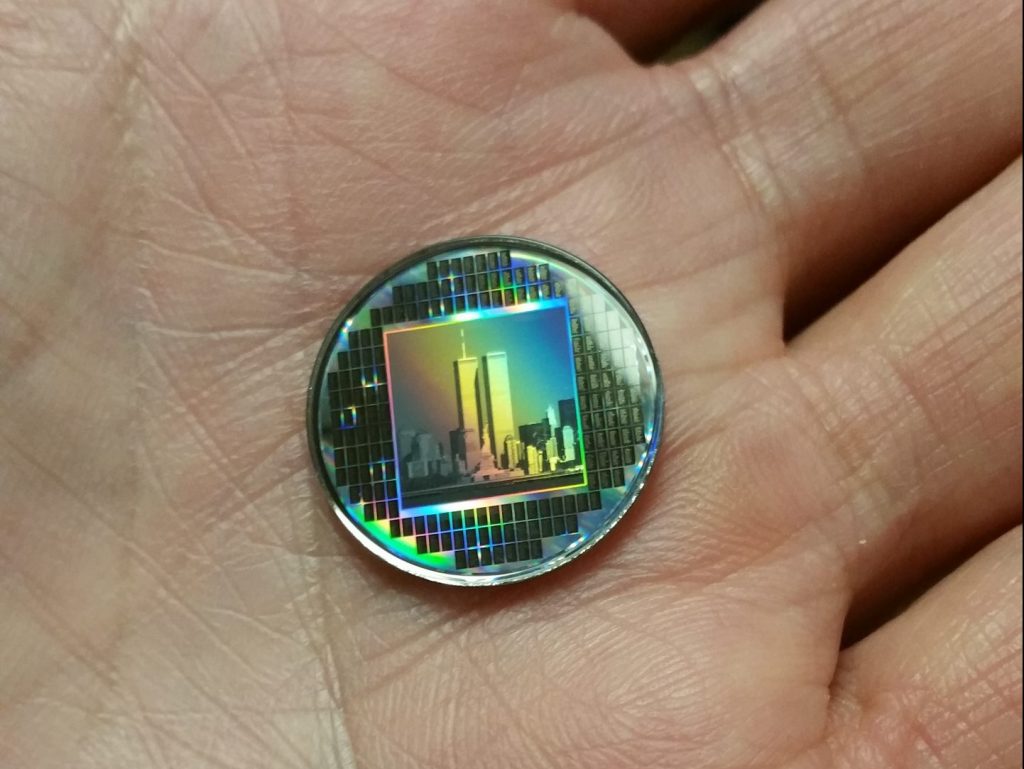

2,750 names of victims lost on 9/11.

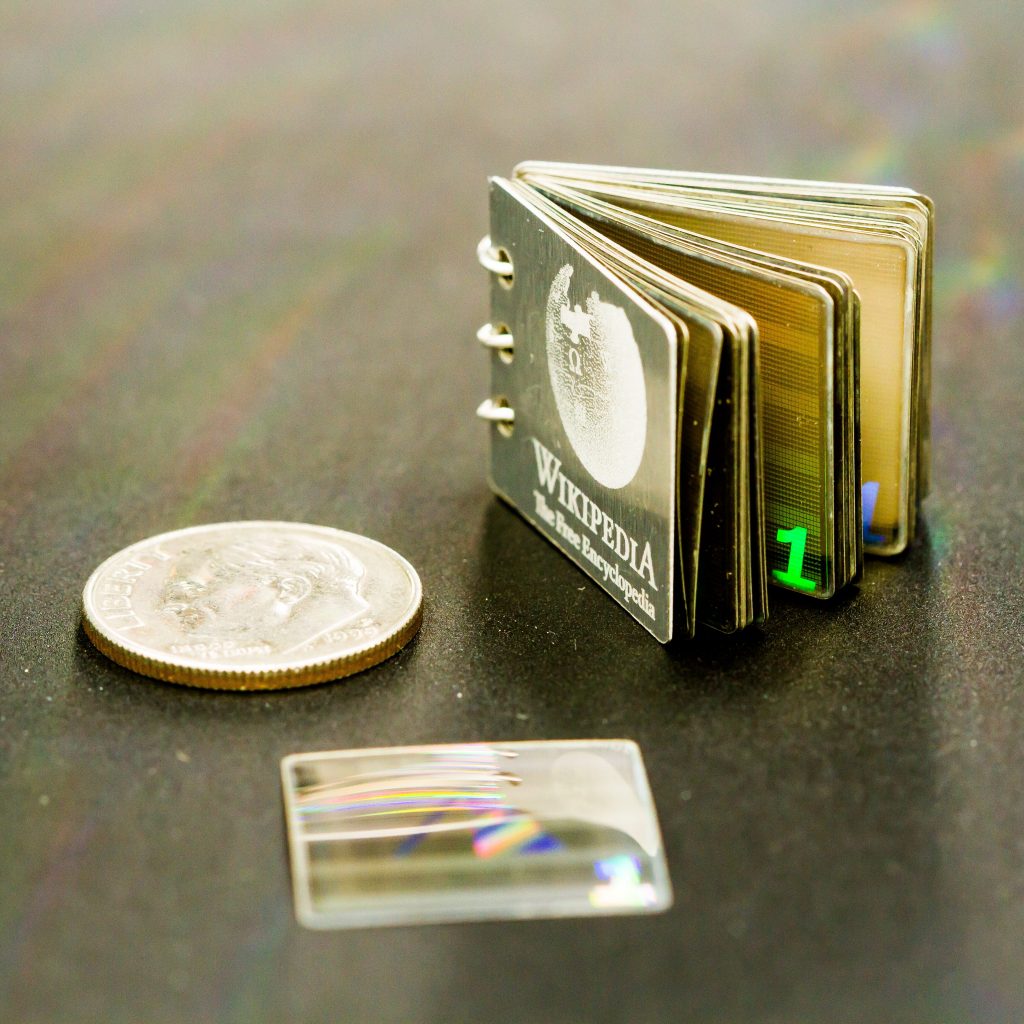

Wikipedia printed on a nickel book with each leaflet holding 8,000 pages.

Equivalent of 150 books stacked 2 stories high.

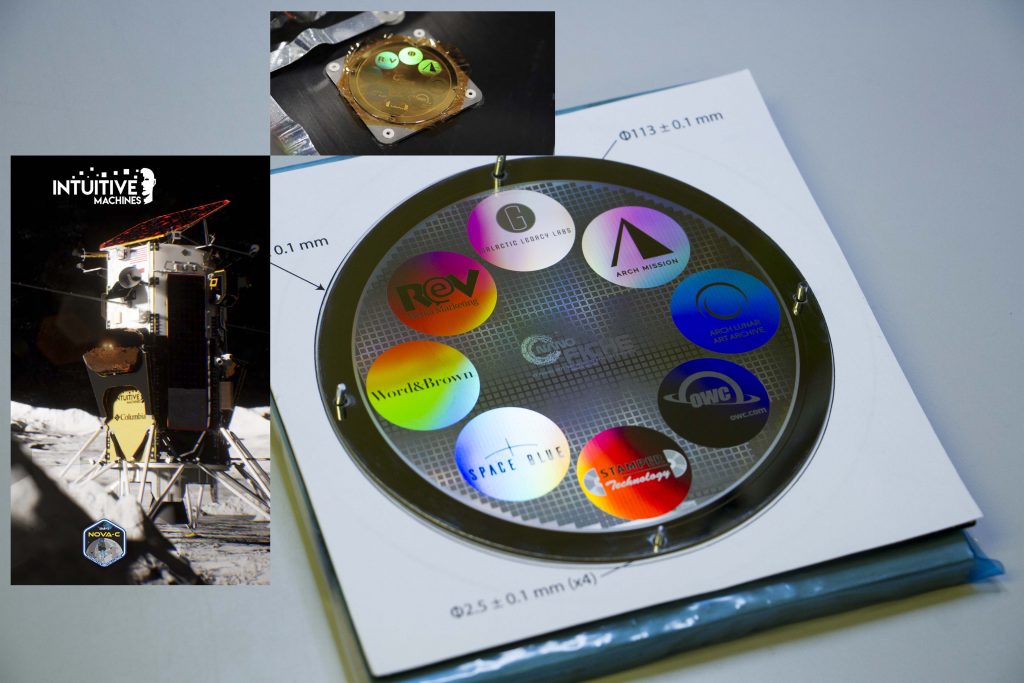

Nickel Library currently preserved with the Intuitive Machines Odysseus Lander.

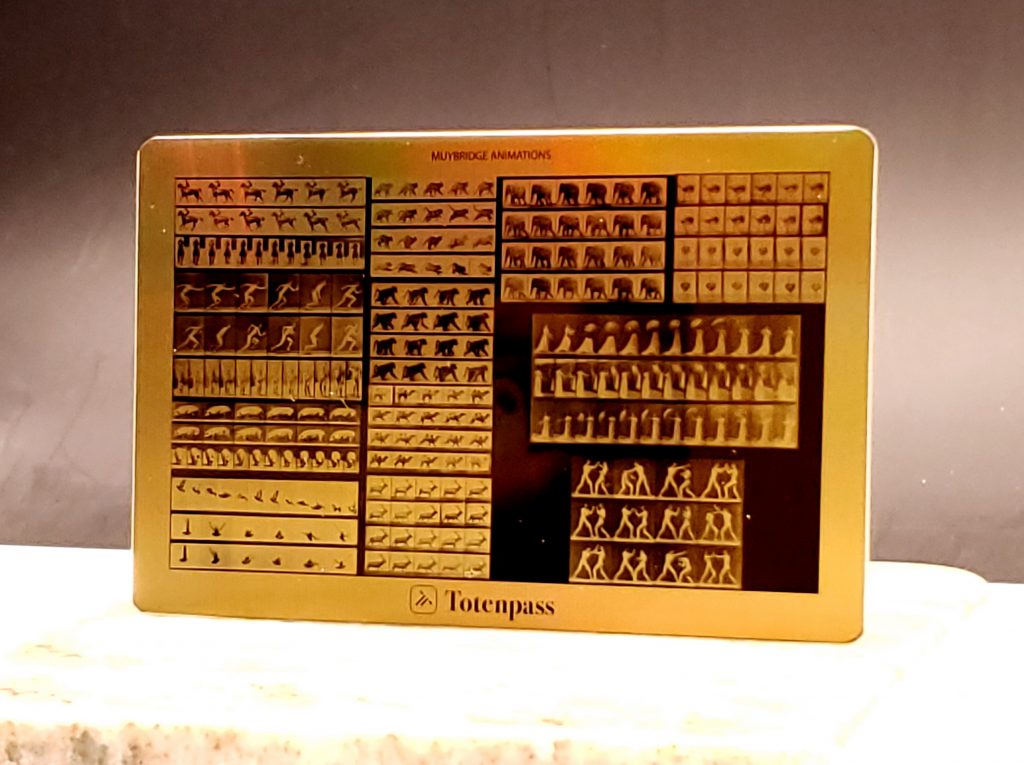

The very first motion picture frames preserved in gold.

NanoFiche technology writes at a resolution of 300,000 dots per inch (dpi) as a binary of metal vs missing metal. The system engraves at a speed of 1,000 pages a minute. The process excels at creating analog hard copies into metal for a permanent record. Although the engraving is black and white, a color separation can be process to create color channels which are recorded to preserve the exact original color. Currently the predominant storage is of documents and photos, digital information is also stored when converted to a hexadecimal or high density QR like code.

This is a permanent, high density, and fast replacement for aging technologies like microfilm which will last typically a generation. NanoFiche, made of nickel and gold, is inert to last for the life of the metal. Left alone it has an expected age of millions of years.

The entire Wikipedia Encyclopedia can be printed on nickel in less than a month and stored in a bank box. Unlike high density microfilm, eye readable images are recorded on a nickel disc, readable with a microscope and indexed through a mapped matrix.

Because of the high density recording, a bank box that typically can hold 2,000 letter sized pages, can hold an astonishing 350,000,000 equivalent pages. A 1/4 inch stack of 12mm NanoFiche can hold an equivalency of books stacking over 2 stories high. The same stack at 28mm holds up to 600 books.

For very long time cold storage, the best systems are analog. This has several advantages. One it is very easy to decode. Even if the information is in a different language, a decoder key such as the Rosetta key made by the Long Now Foundation can be used to retrieve information.

Current information storage system, either analog or digital, require migration when new technology becomes available. Microfiche is a film that stores analog information by an optical reduction process. The film is volatile and warps with temperature and easily burnt up with a match. Digital storage mediums are also susceptible to temp and humidity variations. Expensive HVAC systems are needed to maintain all existing storage systems. NanoFiche changes that paradigm and can easily be stored in a warehouse and survive a fire with no need for any energy consumption for maintenance. As a resilient analog format it does not require new technologies to migrate to.

F.A.Q.

Frequently Asked Questions